The other half say that torch down is the wrong way to go because the seams or top layer begin to crack within 5 years and the application can be dangerous if not done properly i e.

Rolled roofing vs torch down.

As it is rolled out the roofing professional will use a torch to heat the bottom of the cap to the top of the base sheet.

Rolled asphalt is the least expensive and least reliable roofing option for low sloped roofs hence the difference in price you see.

In a two layer torch down roof the system is complete at this point.

Depending on your roofing systems design one of these membranes might be a better choice than the other.

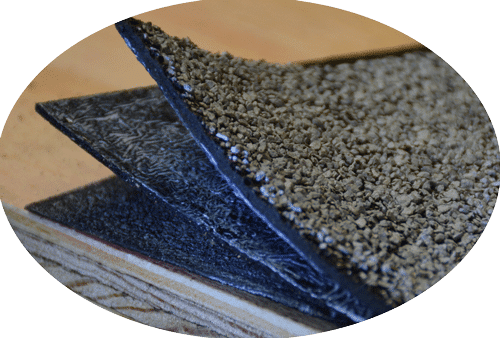

If not a third layer with granules is applied in the same way.

A single ply rolled roof similar to ice and water shield but impregnated with a mineral based wear surface.

The three foot wide rolls are laid in position and the roofer will begin to apply heat to the exposed portion of the roll and kick it a foot then heat the next exposed portion of the roll and so on see the cover.

When the two layers are pressed together they form a seal.

The difference between torchdown roofing and regular roofing is.

Climates with frequent snow are a challenge for flat roofs because snow stays on the roof until it melts.

Torch down roofing on the other hand consists of fewer steps and while roofers will still be exposed to the heat of the torch they will not have to use liquid tar.

The installation of torch down roofing involves the use of a hand held torch fed with propane from a tank.

Torch down systems involve heating the adhesive as the material is unrolled.

Newer peel and stick systems are safer and easier.

Torch down roll roofing is designed for all climates expanding under heat and contracting under cold conditions without melting or cracking as other materials might.

Potential hazards aside from the always present hazard of taking a tumble from the roof these two roofing processes each provide different hazards for roofers.

Of roofing then replacing one section of the roof at a time is the way to go.

These guys instead are proposing using a cold process with a slightly thinner material typically tamko awaplan rubberized roll with elastomeric adhesive.

Peel and stick material can be installed by homeowners.

As the name implies it involves the use of a blowtorch to melt a petroleum based substance called bitumen to creat.

With higher quality torch down roll roofing you may have to pay a little bit more at installation.

Torch down roofing is used on flat or low sloped roofs.

It s this ability that gives torch down roofs their long lifespan.

Single ply membranes such as pvc epdm tpo or torchdown also known modified bitumen are the most common low slope and flat roofing materials.

However you will also get a longer lasting roof that needs fewer repairs during its lifetime which will end up saving you money in the end.